Service and Maintenance

What to expect from Nemag and how we service our clients

You want a grab and service you can rely on.

Fortunately, Nemag's strong reputation as a family business since 1924 wasn’t only built on delivering high-end products. We supply tailored dry bulk grabs to achieve the highest productivity against the lowest maintenance costs per ton transferred.

Above all, Nemag has a 100% service guarantee. We offer spare parts for the entire lifetime of the grab and will always provide advice if a challenge arises. So feel free to contact us or find out more about our support.

Components and spare parts

Spare parts and components are available or produced upon request. They can be orderdered with your grab’s purchase and requested for the entire lifetime of your grab. Nemag strives to use grab components like bearings and plate materials which are internationally standardised and widely available. As a result, you can easily source your replacement parts locally without hassle.

While grabs with the lowest maintenance costs still need to be maintained, you can minimise downtime by keeping original spare parts in stock. We will happily provide you with the advised quantity of spare parts for every order. The spare parts list, including prices, can also be sent upon request.

Transport and assembly

With our extensive network of transport operators worldwide, we offer fast and reliable shipping everywhere. This network enables us to provide fast, reliable shipping at competitive pricing. For a seamless experience, you can also request FOB or CIF conditions, including lashing and transport to the loading port.

If preferred, we can ship the grabs modularly, disassembled, using container shipment. This drastically reduces your costs of ocean freight and transport fees.

Following arrival at the unloading port, Nemag provides the following services for (disassembled) transport:

- Unloading plan

- Detailed assembly instructions

- Detailed assembly video

- Assembly is simple and can be conducted independently in 1 to 3 days.

- We can also provide assembly guidance on location upon request.

Operation and Maintenance Manual

Your new grabs should be easy to work with by more than just your approved operator. That's why we developed an extensive Operation and Maintenance manual. This manual provides helpful knowledge on preparing, operating and maintaining the grabs to everyone from the owner, to authorised personnel and maintenance engineers.

These subjects include the manual documentation:

- Descriptions and overview

- Safety

- Installation

- Operation

- Appendices such as drawings, forms, inspections or additional datasheets

- Maintenance schedules

- Maintenance procedures

- Transport and storage

- Technical data

- Troubleshooting

Brochures, Quick guides and user manuals

View our drybulk grab product pages to download the available brochures and quick guides. User manuals are publicy available for the rope pear sockets and quick release links.

The operation and maintenance manual for grabs can be sent upon request and is always shared upon purchase. We advise performing a basic inspection every 10,000 grab cycles or after a collision or unintended use. Execute an extensive inspection after every 100,000 grab cycles and after maintenance.

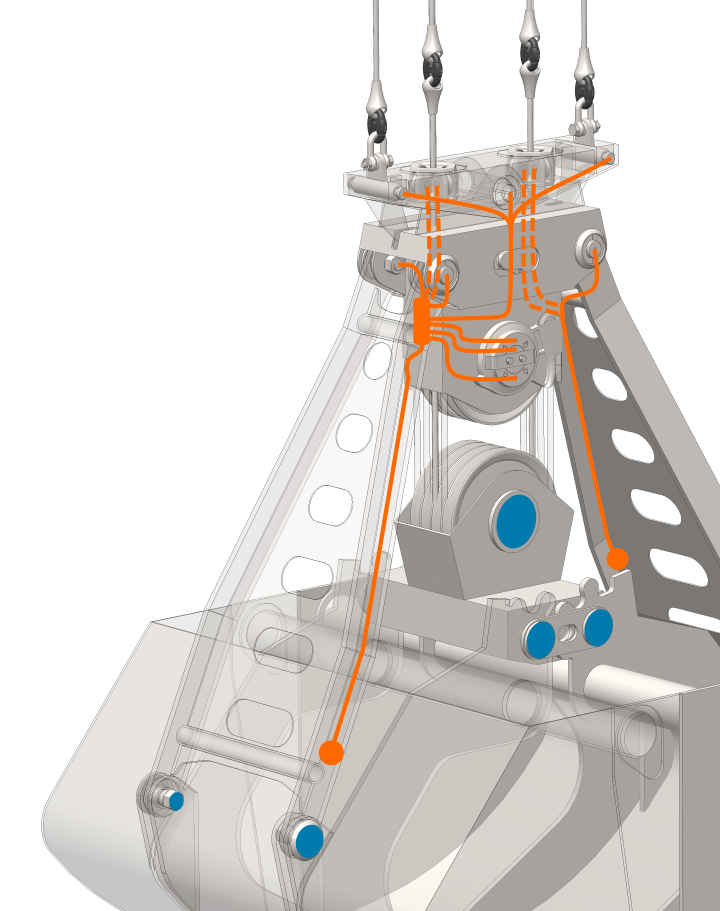

Central greasing system

We understand your requirement for a safe working environment for your staff and our focus on productivity. This is why all Nemag grabs operate with a centralised greasing system.

Greasing all the moving parts is essential to reduce wear and to increase the product’s lifespan. But lubricating multiple grease nipples can be a tedious job and sometimes a far reach! This system enables fast and safe greasing of the entire grab without dangerous climbing.

In short, a central greasing system improves your productivity and reduces your safety risks.

Lubrication details

If the grab was not in operation for an extended period, apply grease to all lubrication points before operation. Nemag grabs have grease nipple types 1-4” & 1-8”. The normal grease volume per nipple is 10 cc. Grease type and frequency can be found in your operation and maintenance manual. Your manual can be resent upon request.

Nemag quality

Nemag offers a 100% service guarantee. We’re not just a grab vendor; we’re a partner. If you have a service or grab-related question, feel free to contact Nemag or your Nemag representative directly.

To reduce downtime and service needs, we strive to deliver a state of the art quality. Learn more about what to expect from Nemag's high end quality.

Request a free quotation

Do you want to improve your productivity and reduce your maintenance costs? Request a free dry bulk grab quotation or schedule a meeting.

We will provide detailed pricing information on your new dry bulk grab within 48 hours.

Contact

If you have any questions please feel free to contact us.

We are happy to help you!

You can improve your acceleration with...

...%

RECEIVE A PERSONALIZED REPORT ON HOW TO INCREASE YOUR PRODUCTIVITY

Thanks for your interest

We have sent you an e-mail with a more detailed report

Oh my grab!

To calculate your productivity increase we need additional information. As we’re not familiar with your current installation. Please share your email address for us to contact you.

Thanks for your interest

We will get back to you as soon as possible

Compare the grab glossary

Crane capacityIs the Safe Working Load of your crane in tons in grab duty, i.e. the total sum of grab dead weight and payload.

PayloadIs the nett load of cargo in the grab. Because it’s linked with the grab weight it will be filled in automatically.

Grab weightIs the Dead weight of your existing grab. Not sure? Check your grab manual, CE declaration, or on the ID plate on your grab.

Grab rope withdrawal lengthIs the length of the closing rope which needs to be pulled out in order to close the grab (not to confuse with the total reeved in grab rope length).

Not sure about the numbers?Check the grab manual. Don’t hesitate to contact us.

+31 (0)653109307