Constantly looking for ways to increase productivity and lower operational costs is necessary to keep a frontrunner position in the market. An excellent performing crane is key in order to achieve this objective.

Did you know that crane performance largely depends on the type of grab you’re using? Switching the grab greatly benefits your loading and unloading procedure and can even increase productivity by 20% like in the VLI PECÉM case study.

But how to find the best grab solution for your bulk handling operations? This blog compares two grab types - the Clamshell and the NemaX - and outlines their benefits to help you boost your terminal performance.

The best match for your terminal operations

Obviously, mapping out your options starts with the type of bulk material you’re handling. Do your materials have a density of 1.5 to 3 and upwards and/or granulation of <50 mm? Then the NemaX grab - the latest innovation in the market - is your best shot. Otherwise, the Clamshell grab may be an attractive option. Curious to find out if a NemaX grab suits your terminal operations? Check out our NemaX Quick Guide.

Boost productivity by increasing dock flexibility

A fast and lightweight grab significantly increases the productivity per hour, resulting in faster unloading times. More efficient unloading processes increase your dock flexibility and berth planning. In this way, you're not only maintaining a streamlined unloading process, but you’re also saving a lot of time and thousands of unwanted fees!

The innovative NemaX grab is designed with this challenge in mind and is, therefore, one of the fastest and lightest grabs in the market. Test the Nemax Grab for free at your own terminal and discover the benefits first hand!

Reduce your Total Cost of Ownership

Energy costs are among the terminal's biggest expenses. With a more innovative grab, you can realize significant savings in this area. Both the clamshell and NemaX are highly productive grabs that consume substantially less power per ton material transferred, leading to an even higher ROI.

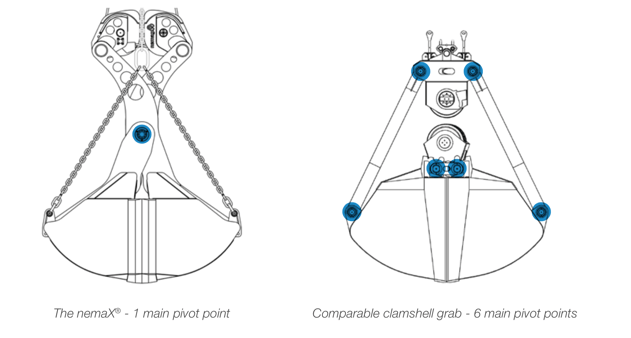

In addition, the NemaX holds a second key advantage regarding the reduction of Total Cost of Ownership. It requires much less maintenance due to fewer moving parts and pivot points. This not only saves you maintenance costs but also assures the highest possible uptime!

Ensure the safest working conditions

During the trimming phase of the unloading process, several bulldozers and personnel are deployed to move material from the edges to the center of the vessel, which can create hazardous situations. The NemaX’ extremely horizontal opening enables you to reach edges more easily, resulting in:

- Less machinery and people are needed within the vessel to move bulk material

- Enhanced safety in the hatch due to reduced risk of avalanching

- Reduction of (labor) costs and accelerated unloading times

All of the above, and the fact that changing the closing cables is much less dangerous due to the low working height, makes the NemaX one of the safest options.

Find the best grab for your dry bulk operations

Are you looking for ways to find out which of our grab solutions - the NemaX, Clamshell, or one of our other grab solutions - best suits your bulk material? Use our grab selector and quickly find the grab that realizes the highest productivity for your operations.

Download the brochure or quick guide if you want more information on the Clamshell or NemaX.

Wondering how the innovations of the NemaX boost the efficiency of your operations? Try our NemaX demo grab for free and easily implement it into your daily bulk handling. Click the button below to request more information: