NEMAG: PASSION FOR PERFORMANCE SINCE 1924

Optimal efficiency through research, innovation and people

Since Abraham Grootveld developed his first grab and launched Nemag back in 1924, the world has changed significantly. Through constant innovation and by closely listening to and working together with our customers to create optimal solutions, we are proud that we can still convey Abraham's Passion for Performance to this day.

At Nemag, we have always believed in the power of innovation. But it takes more to continuously improve to develop equipment that is more efficient, cost-effective and competitively priced: our Passion for Performance.

-

A passion that drives all our employees and everything we do.

-

A passion that has won us countless industry and non-industry awards.

-

A passion that is relied upon by numerous customers around the globe.

-

A passion that we want to share with you. Now and in the future.

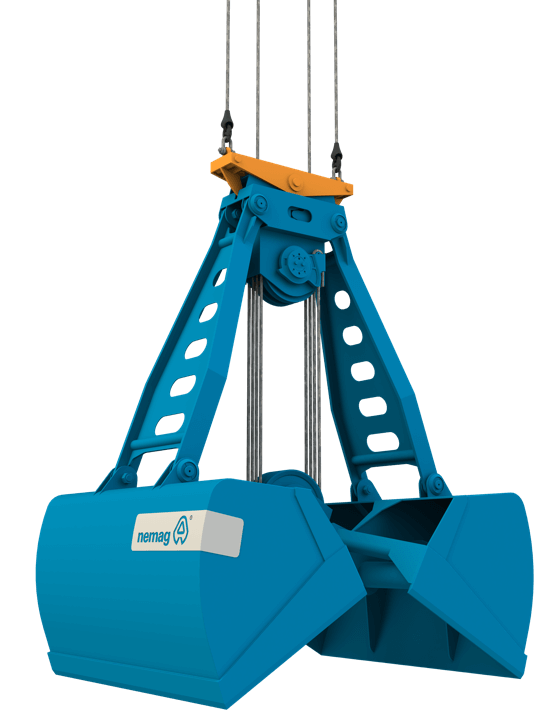

Explore our innovative and comprehensive solutions for handling dry bulk, from coal and iron ore to wheat, scrap metals, minerals and clinker. Our range of four-rope operated mechanical grabs together with our high-quality rope connection systems means we can always provide an optimal solution to meet your requirements.

Highly productive grabs and innovative solutions

To meet your specific requirements we have developed a range of dry bulk grabs. Each grab has its own advantages for your specific application. Increased production, low operational costs, enhanced safety, environmentally friendliness and reduction of the use of trimming equipment have been taken into consideration when developing our grab solutions.

The technological development is partly financed by the European Regional Development Fund in the framework of the OP Zuid.

Technological development

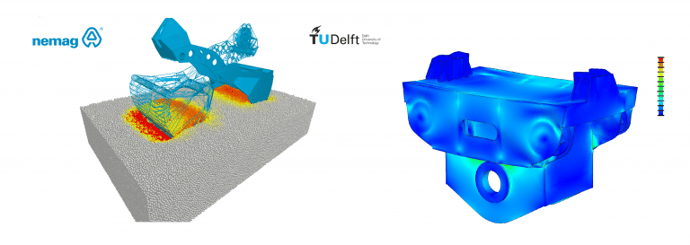

In close cooperation with leading bulk terminal operators, crane manufacturers, Technical Universities and other stakeholders in the industry, Nemag continues to develop new products for the dry bulk industry. The aim is always to reduce handling costs per tonne of dry bulk materials transferred.

The latest software technology like 3D CAD, Multi Body Dynamics (MBD), Discrete Elements Methods (DEM) and Finite Elements Methods (FEM) support our team of designers in optimising your grab. High tensile steels, wear resistant steels and advanced bearing technology enables us to design extremely productive, light weight and durable grab mechanisms.

Nemag inventions include the scissor grab, specialised rubber-lined lip sealing systems for handling powdered cargo, the patented Nemag quick-release link and the Nemag rope pear socket for high strength wire ropes, the introduction of a new generation of environmentally-friendly clamshell grabs, and last but not least, the patented and awards winning NemaX grab.

Nemag is rewarded by the Dutch Chamber of Commerce with the 20th position of most innovative companies (MKB) in the Netherlands.

CUSTOMER SUPPORT

Alongside innovation, customer support and a very intensive after-sales service are of paramount importance to both Nemag and its customers. A global network of specialised representatives supported by Nemag specialists are ready to assist customers worldwide.

Leading steel plants, bulk handling companies and crane manufacturers in over 60 countries worldwide are part of our customer base for decades: companies which, just like us, stand for innovation, quality and reliability.

Have a look at our company video and find out about us!

Nemag's values

- Reliable: a strong reputation since 1924.

- Innovative: long term partnerships with stakeholders in the industry.

- Leading: paramount grab technology and in-depth know-how.

- Advising: our expertise results in the best solution.

Service and Quality

As a driver of innovation in the dry bulk market we value continuous improvements, both in our products as in our relations.

Discover what you can expect at Nemag from a service and quality perspective.

Want to know more?

If you have any questions please feel free to contact us.

We are happy to help you!

- Home

- About us

You can improve your acceleration with...

...%

RECEIVE A PERSONALIZED REPORT ON HOW TO INCREASE YOUR PRODUCTIVITY

Thanks for your interest

We have sent you an e-mail with a more detailed report

Oh my grab!

To calculate your productivity increase we need additional information. As we’re not familiar with your current installation. Please share your email address for us to contact you.

Thanks for your interest

We will get back to you as soon as possible

Compare the grab glossary

Crane capacityIs the Safe Working Load of your crane in tons in grab duty, i.e. the total sum of grab dead weight and payload.

PayloadIs the nett load of cargo in the grab. Because it’s linked with the grab weight it will be filled in automatically.

Grab weightIs the Dead weight of your existing grab. Not sure? Check your grab manual, CE declaration, or on the ID plate on your grab.

Grab rope withdrawal lengthIs the length of the closing rope which needs to be pulled out in order to close the grab (not to confuse with the total reeved in grab rope length).

Not sure about the numbers?Check the grab manual. Don’t hesitate to contact us.

+31 (0)653109307